From the technical definition of the requirement to the installation of the product, our engineering team of experts will assist you throughout your project.

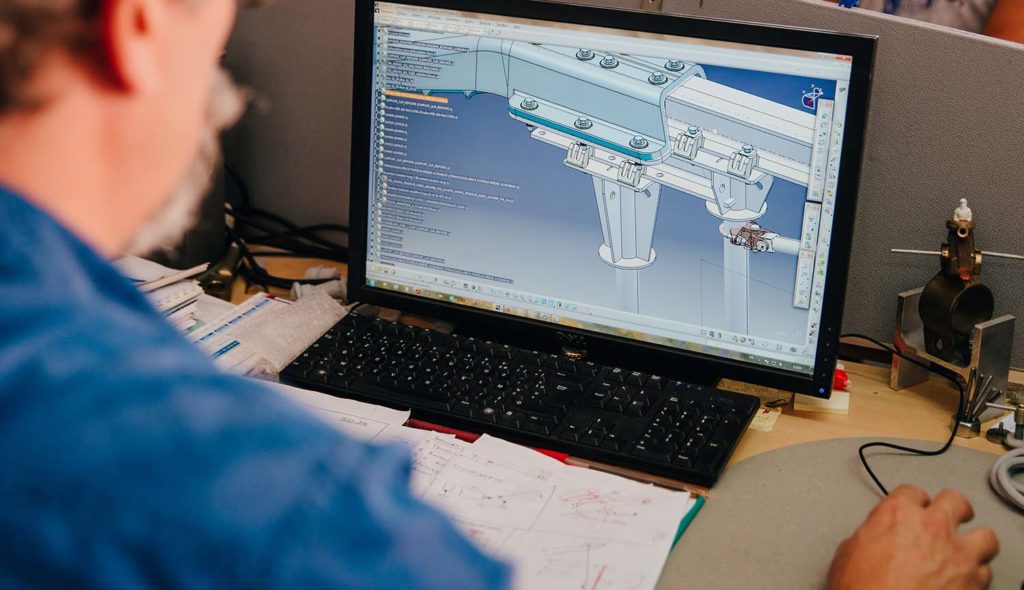

Technoforme Engineering was created to meet the growing need for expertise, innovation and creativity of our customers, while reducing design and development times. We have equipped ourselves with the latest state-of-the-art tools (CATIA V5 R24 stations, printer and 3D scanner in particular) in order to develop ever more efficient and secure products for our customers. We intervene on site if necessary, wherever you are, Technoforme Engineering can quickly be at your side.

Our project managers work closely with you and manage quality, cost and deadlines based on the Group’s various departments. The PeP’S project management process developed by our teams for our teams guarantees optimal risk management as well as regular progress reports with the actors of your project.

Our team of engineers and draftsmen work with you to define the main functions of your product and help you specify your needs if necessary. Their ease and agility with our 3D rendering, 3D modeling and 2D drawing software ensures you optimal reactivity and quality of deliverables, from the technical offer to the illustrated catalogue of your products.

In collaboration with our Laboratory, we establish the mechanical characteristics of the materials we use. Our Calculation team can thus optimize the design of your products by exchanging with our Design and Industrialization department.

According to your needs, our team is able to push the industrialization of your products as far as you wish: definition of tools, installation of reinforcements and fasteners, definition of drapeings, patterns or various templates, the file can be delivered turnkey.

For some projects, we offer the customer the transfer of our technology to the Group’s subsidiary closest to its own manufacturing unit.

We have many years of experience in this organisation and provide the client with a well-tried procedure and dedicated staff who ensure the follow-up and validation of transfer operations. Visit the Our Subsidiaries page to learn more about us!