Analysis & Re-engineering

La numérisation 3D permet, entre autres, de vérifier, contrôler nos pièces pour s’assurer que celles ci soient correctement produites et déterminer les raisons d’éventuels écarts, qu’il soit en composite, ou en métal.

Grace à notre savoir-faire, nos technologies avancés et notre expertise en ingénierie 3D, nous garantissons chaque étape de la gestion du cycle de vie produit, du développement, à l’inspection finale.

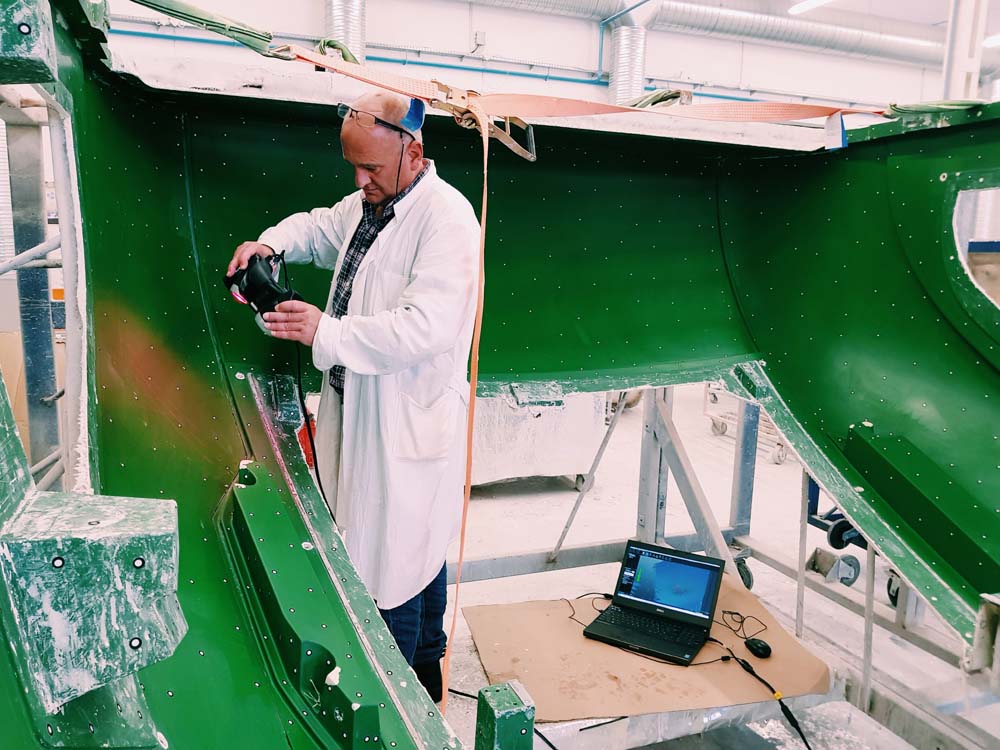

Development and production increasingly require the use of fast and reliable quality control systems for part inspection. As a supplier, our Group is committed to meeting all design and specification requirements.

The comparative inspection of the first parts and the CAD model is essential for product development, 3D analysis produces accurate and fast results ensuring that the part is correctly produced.

Before each new production is launched, the inspection of the moulds and their jigs is checked to ensure that each element has the correct geometry.

No technical file in your possession for your repairs or renovations? It is not a problem, we come to scan your parts and their environment in order to reconstruct a digital model, which will allow us to work with complete and accurate basic elements.

In large 3D printing (300x300x600mm), 1:1 scale model made in our tooling and modelling workshop or in serial materials, we go as far as manufacturing your tooling and/or prototype, to present it to your teams or your customer.